Rotational Molding Design Materials Processing

[PDF] Rotational Molding Design Materials Processing Ebook

Rotational Molding Design Materials Amp Processing Glenn

Hanserpublications Com Rotational Molding

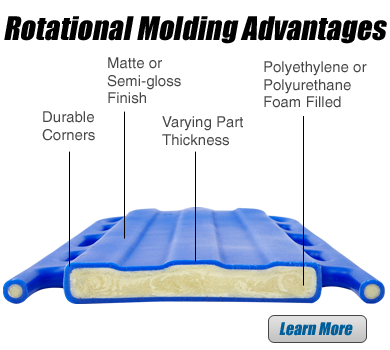

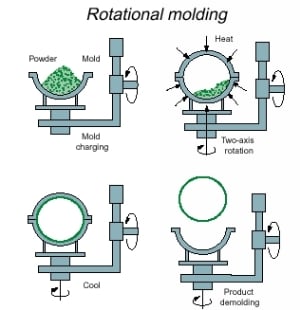

Rotational molding - Wikipedia Rotational molding developed further and R.J. Powell used this process for molding plaster of Paris in the 1920s. These early methods using different materials directed the advancements in the way rotational molding is used today with plastics. Plastics were introduced to the rotational molding process in the early 1950s. Rotomolding Design Design for Rotomoulding? Rotomolding Design. The process of designing a mold or tool to create a rotomolded part should involve an engineer who understands the principles of rotational molding and rotomolding design.Rotomolding produces hollow parts and has the capability of producing double wall parts depending on mold design. Rotomolding Process What is ... - Rotational Molding Pulling part from a mold at the end of the Rotational Molding process. Material being weighed out for the Rotational Molding Process. A variety of materials are available for rotational molding though the most widely used is polyethylene. This outstanding material is an integral part of the rotational molding process.

Roto Molding Lifeark

Rotational Molding Roto Molding Custom Rotational

Rotationally Moulded Tanks

0 Response to "Rotational Molding Design Materials Processing"

Post a Comment